The logistics industry is changing fast, and businesses must prepare early. A future-ready logistics strategy is essential to meet rising customer expectations, faster delivery cycles, and growing competition. As we move toward 2025 and beyond, companies need smarter systems, strong partnerships, and sustainable operations to stay ahead. Therefore, planning today will help ensure long-term success tomorrow.

Building a Strong Digital Foundation

To begin with, 2025 will demand quicker decisions and better visibility. A future-ready logistics strategy starts with strong digital systems. We are upgrading dashboards, automating reports, and using real-time data. As a result, teams can respond faster and reduce errors. Moreover, digital tools reduce manual work and improve accuracy across operations.

Investing in Smarter Technology

Investing in Smarter Technology

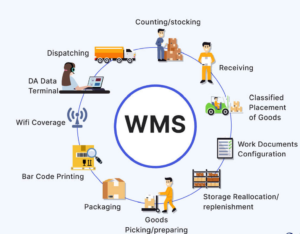

In addition, technology plays a key role in a future-ready logistics strategy. Automation tools help speed up daily processes and minimize mistakes. For example, smart systems improve order tracking and inventory control. Consequently, teams work more efficiently, and customers receive better service. Over time, technology will continue to support scalable growth.

Strengthening Customer Partnerships

Equally important, strong relationships are the backbone of a future-ready logistics strategy. Customers expect clear communication and reliable service. Hence, we are improving response times and creating dedicated support channels. This approach builds trust and encourages long-term partnerships based on transparency.

Building a Skilled and Agile Team

Finally, people drive success. A future-ready logistics strategy depends on a skilled and adaptable workforce. We are training teams in digital tools, communication, and problem-solving. This helps them handle change confidently and deliver better results.

Conclusion

In conclusion, preparing for 2025 requires clear planning and bold action. By adopting a future-ready logistics strategy, businesses can achieve smarter operations, stronger partnerships, and sustainable growth. Ultimately, the focus is on building systems and teams that are ready for the future.

Collaborative Robots (Cobots)

Collaborative Robots (Cobots) Conclusion

Conclusion