How Centralized Warehousing Solutions Solve Inventory Problems

India’s business ecosystem is expanding rapidly. From startups and regional manufacturers to large FMCG brands and e-commerce sellers, companies across sectors are experiencing growth in order volumes and geographic reach.

However, as businesses grow, inventory management often becomes one of the most complex operational challenges. What worked at a smaller scale—manual stock records, scattered storage locations, and informal processes—quickly breaks down as volumes increase.

Why Inventory Management Becomes Difficult as Businesses Grow

In the early stages, inventory is relatively easy to manage. Stock levels are limited, and operations are simple. But growth introduces complexity.

Common challenges include:

- Inventory spread across multiple locations

- Lack of real-time visibility

- Overstocking to avoid shortages

- Stockouts due to poor planning

- Rising storage and logistics costs

- Difficulty managing returns and damaged goods

These challenges are particularly common in India, where supply chains often span multiple states and demand fluctuates seasonally.

The Hidden Cost of Poor Inventory Management

Poor inventory control does not only affect warehouses—it impacts the entire business. Inaccurate inventory leads to delayed deliveries, cancelled orders, unhappy customers, and increased working capital blockage.

For growing businesses, these inefficiencies can slow expansion and reduce competitiveness.

Why Decentralized Storage Creates Problems

Many Indian businesses rely on decentralized storage—small godowns in different cities or regions. While this may seem convenient initially, it often results in:

- Duplicate stock across locations

- Higher rental and manpower costs

- Inconsistent handling practices

- Poor coordination between warehouses

As order volumes grow, managing multiple storage points becomes operationally expensive and difficult to control.

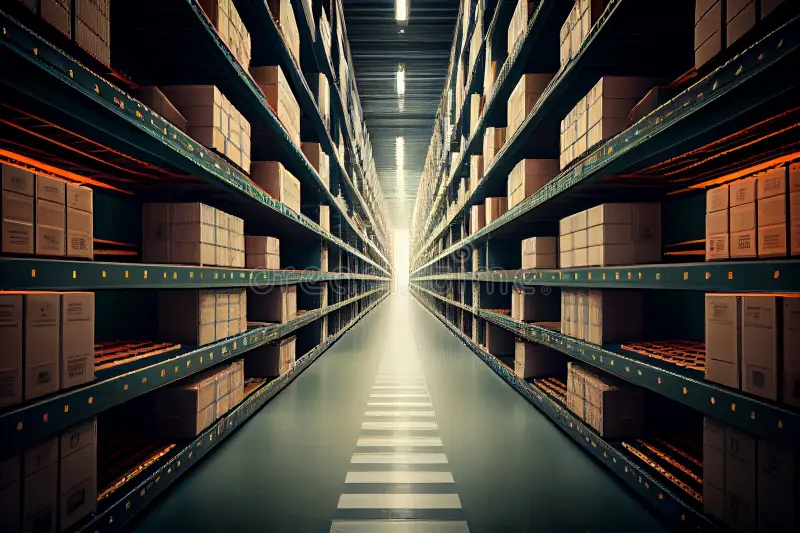

Centralized Warehousing as a Solution

Centralized warehousing offers a structured alternative. Instead of managing inventory across several locations, businesses store stock at one strategically located hub.

Locations like Bhiwandi, with strong connectivity to Mumbai, JNPT Port, and national highways, make centralized warehousing highly effective.

Benefits include:

- Single point of inventory control

- Better visibility and reporting

- Reduced duplication of stock

- Faster planning and replenishment

- Lower overall logistics costs

How FIFO Improves Inventory Flow

FIFO (First In, First Out) is a critical practice in centralized warehouses. It ensures that older stock moves out before newer stock.

FIFO is especially important for:

- FMCG and food products

- Pharmaceuticals

- Cosmetics

- Chemicals and consumables

By following FIFO, businesses reduce product expiry, quality issues, and write-offs.

Role of Organized Warehousing Processes

Centralized warehousing works best when supported by organized processes such as:

- Defined storage locations

- Batch-wise inventory tracking

- Standard receiving and dispatch procedures

- Regular stock reconciliation

Professional warehousing partners help businesses implement these practices consistently.

How Akash Storage Supports Growing Businesses

Akash Storage supports Indian businesses with centralized warehousing solutions in Bhiwandi that are designed for scale. With structured layouts and disciplined inventory handling, businesses gain better control as they grow.

Long-Term Impact on Business Growth

Businesses that move to centralized, FIFO-driven inventory systems experience:

- Improved order fulfillment

- Reduced losses

- Better customer satisfaction

- Stronger supply chain resilience